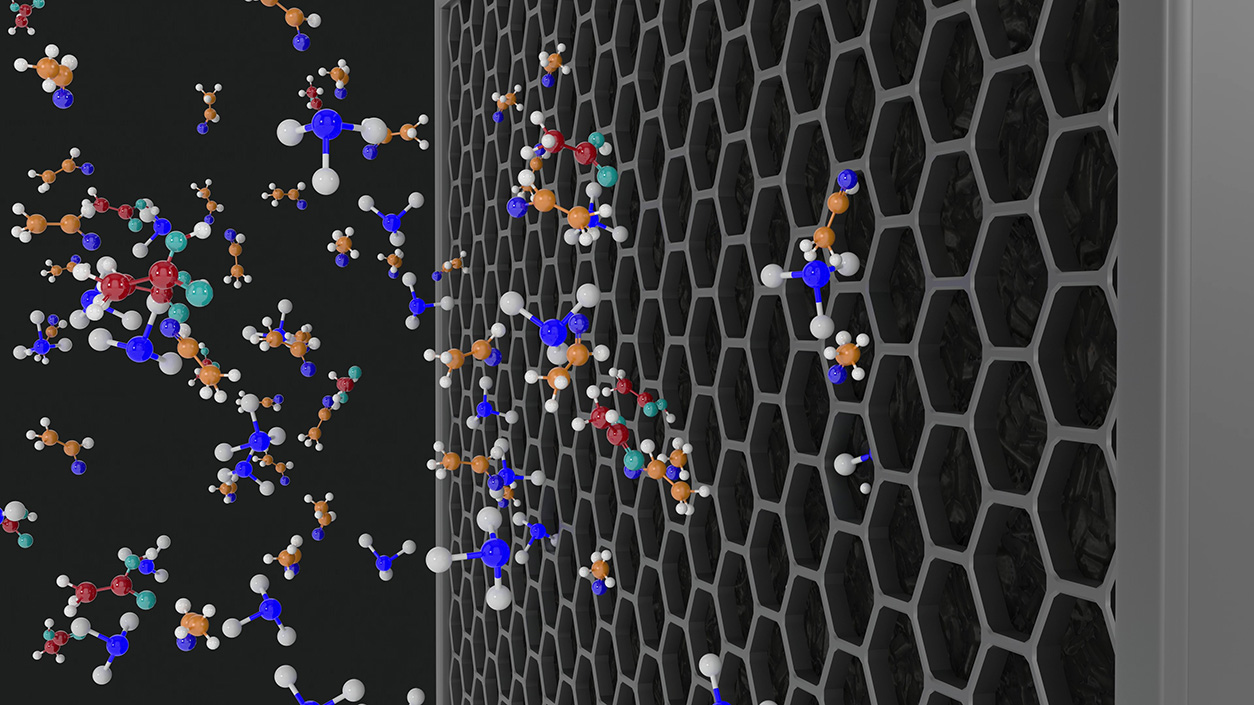

Selecting the appropriate industrial air filters is essential for maintaining a clean and safe working environment. Airborne contaminants, such as dust, pollutants, and particulate matter, can pose health risks and negatively impact productivity if not properly filtered. In this blog, we will explore important factors to consider when choosing industrial air filters to ensure optimal air quality and worker well-being.

The first and foremost factor to consider is the filtration efficiency of the filter. Different filters are designed to capture specific particle sizes and contaminants. Look for filters with high-efficiency ratings in removing the particular pollutants present in your industrial environment. For example, filters with fine fibers are effective against small particles, while coarser filters are better suited for larger debris.

The airflow capacity of an industrial air filter is crucial for maintaining proper ventilation while efficiently removing contaminants. Ensure that the selected filter can handle the required airflow rate without excessive pressure drop, as it can lead to increased energy consumption and decreased overall system performance.

Consider the filter’s service life and maintenance requirements. Longer-lasting filters help reduce operational costs and minimize downtime due to frequent replacements. Regular maintenance, including cleaning or changing filters, is vital to ensure consistent filtration efficiency and a healthier environment for employees.

Different industries have unique air quality requirements. For example, manufacturing facilities may deal with oil mist or welding fumes, while pharmaceutical industries need to address airborne particles in sterile environments. Understanding the specific needs of your industry will help you choose filters that best suit your environment.

While efficiency and performance are essential, cost-effectiveness is also a significant consideration. Compare initial investment costs, maintenance expenses, and filter longevity to find the best balance between performance and budget.

Investing in appropriate air filtration systems not only promotes worker health and productivity but also demonstrates a commitment to environmental stewardship. By incorporating the right industrial air filters, you can ensure optimal air quality, reduce respiratory risks, and create a safer and more sustainable workplace for all.